XECARB® thermoplastic composites in Bft motors

Xenia® Materials introduces the new application of XECARB® thermoplastic composites.

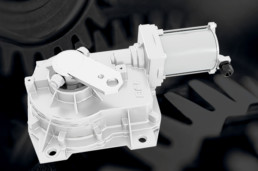

Xenia®’s carbon fiber reinforced product is found in the new ELI AC/BT A: the range of underground motors developed by Bft Spa, an Italian company leader in the production of automation systems for accesses’ control.

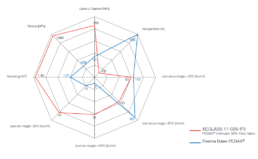

ELI represents the range of in-ground non-reversible electromechanical operators for swing gates. In particular, the durability, the reliability and the silent operation of the AC A 40 and BT A 40 models have been enhanced thanks to the new and exclusive gear realized in XECARB® thermoplastic composite, that has replaced the previous element realized in POM.

With respect to the previous gear, the new one, developed in XECARB® 17 thermoplastic composite, has shown an over two-times higher durability.

With an impact strength value of 120 MPa and an elongation at break of 5,2%, these materials result extremely performing in heavier automation systems, thus guaranteeing a longer lifespan of the product.

Originally engineered for application in the sport system and the aerospace markets, XECARB®17 thermoplastic composites, developed on PEBA, find several applications also in industrial sectors, due to their intrinsic mechanical properties maintained at low temperatures as well.

Xenia® Materials is an Italian company, specialized in engineering and production of innovative polymer-based materials used for the most advanced and challenging industries.

The company, located in Vicenza, incorporates an engineering team, which helps customers to develop high-tech components with a research and development department dedicated to product innovation.

Bft Spa was founded in 1981 in Thiene with one mission: develop cutting-edge technologies in the automation world, in order to simplify the technicians’ job and the final customers’ use.

The innovation, the research of new perspectives to manage the automation systems and the dynamism is part of our DNA and it allowed our company to grow over the years from a family- run business to a small multinational one.

Bft Spa is currently operating all over the world, with 20 branches and over 530 distributors in more than 120 countries.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XELIGHT™

Ultra-light thermoplastic composites

XEGLASS™

Thermoplastic composites

reinforced Glass Fiber

Xenia® thermoplastic composites in the new Salewa® Ortles Couloir mountain boot

Only 725 grams. This is the weight of the newly designed, lightest, fully crampon-compatible mountain boot Ortles Couloir: the new high-tech creation of the Italian eagle brand Salewa®.

The Ortles Couloir boot carries the name of its own theatre of operations: the Ortles Mountain. Boasting a height of 3.905 m, the Ortles is the highest peak of the Rhaetian Alps and it is well known for its very challenging trails.

After winning ISPO Gold Award 2021 in the Outdoor Equipment Mountaineering Boot category, Salewa®’s Ortles Couloir will make its appearance in stores from Fall 2021. Among the cutting-edge materials used to realize this boot, there are also Xenia® Materials’ thermoplastic composites. The toecap is, indeed, produced on a polymeric base supplied by the Italian company leader in the engineering and production of thermoplastic composites reinforced carbon fibre. This carbon solution offers and guarantees both stiffness and flexibility.

The processing of last generation’s carbon reinforced thermoplastic composites and the injection moulding process allow the standardization and realisation of structures with improved and optimized thickness, which would otherwise turn out to be very expensive and difficult to achieve through the traditional lamination process. Thermoplastic composites are, furthermore, easily and efficiently recyclable.

The compact, solid and agile design, characterized by a narrowed toe area, provides the Ortles Couloir with more precision while climbing both rock and ice. The boot’s frame has been brilliantly designed in carbon fibre in order to offer both lightness and stiffness. Moreover, its hinged joint closure ensures greater comfort while walking and more grip while climbing.

«This new boot was inspired by the Dolomite Mountains, our home, – explains William Starka, Senior Product Manager Footwear & Equipment of Salewa® – the absolute innovation in the alpine boots market is represented by its neat design, which allowed us to obtain great precision, total freedom of movement and an excellent stability for rock and ice climbing. To ensure a long-lasting performance, we selected durable and high-quality performing materials. The Ortles Couloir boot has brought the development of alpine boots into a completely new dimension». «Working with Salewa® and its partners has represented a great and exciting challenge. We began by developing a specific customization process which led to the selection of the polymer and a well-defined percentage of carbon fibre. This tailor-made project made us so happy and pleased» adds Enrico Mancinetti, Xenia® Materials’ Sales Manager.

To study and design together with the outdoor footwear brands the best applications of the thermoplastic-based composites, Xenia® Materials has recently started Xenia Footwear Materials Lab project which offers a turnkey service to the footwear industry companies and supports them step by step; from the choice of the material and co-design phase until the testing process and simulation of the footwear in specific circumstances.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XEBRID™

Thermoplastic composites

reinforced Carbon and Glass Fiber

XEGLASS™

Thermoplastic composites

reinforced Glass Fiber

XECARB® thermoplastic composites: the carbon fibre which provides lightness and stiffness to the two-time MTB Marathon World Champion sole

After winning in Grächen (CH) 2019, Leo Páez has conquered, with another outstanding performance, his second World Championship title in Sakarya, Turkey.

At his feet he was wearing Nox, the shoe specifically designed by Vittoria Cycling Shoes, an Italian company leader in the production of mountain bike cycling shoes.

Nox’s sole is entirely realised in XECARB® 1-C30, a thermoplastic composite engineered and produced by Xenia® Materials.

The collaboration between Xenia® Materials and Vittoria Cycling Shoes started a few years ago, when Edoardo Vercelli sensed the possibility to substitute the prepreg epoxy matrix carbon – used in the high-quality cycling shoes’ soles – with XECARB® carbon fiber reinforced thermoplastic composites.

This turned out to be a winning choice, not only because the weight of the shoe significantly decreased, but also because it has been reached the perfect balance between the necessary stiffness to transmit power on the pedals and the right flexibility that allows the best comfort on walking routes. This great combination is the key of Nox’s success.

The soles, produced in XECARB® thermoplastic composites, are guaranteed overtime and they have been precisely designed to facilitate the process of mud clearance and cleat connection, possible thanks to the wider shape of the cleat connection area.

Xenia® Materials is an Italian company, specialized in engineering and production of innovative polymer-based materials used for the most advanced and challenging industries.

The company, located in Vicenza, incorporates an engineering team, which helps customers to develop high-tech components with a research and development department dedicated to product innovation.

Established in 1976 by the professional cyclist Celestino Vercelli, Vittoria Cycling Shoes is an Italian company specialised in the realisation of cycling shoes, 100% made in Italy.

After 40 years of innovation, the origins of the company are as clear as they were in its early days. The technological evolution allowed the company to adapt to change and to exploit new opportunities, maintaining untouched its peculiar curiosity. Vittoria Cycling Shoes is projected towards the future. High-quality products, innovative technologies and continuous studies are at the core of this company.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XEBRID™

Thermoplastic composites

reinforced Carbon and Glass Fiber

XEGLASS™

Thermoplastic composites

reinforced Glass Fiber

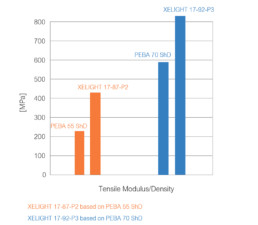

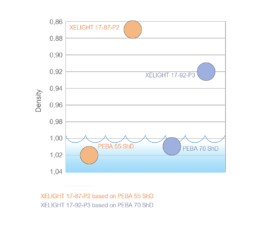

XELIGHT™, the new ultra-light composites family developed by Xenia® Materials, based PEBAX® Thermoplastic Elastomer

Xenia® Materials introduces the new ultra-light composites family entirely developed on Pebax® thermoplastic elastomer, reference polymer in several flagship sports applications.

Due to their exceptional density value, which is below 0,90 g/cm3, XELIGHT™ grades stand out for their incredible lightness. At the same time, they feature a great impact strength, especially at low temperatures, great flexibility and high energy return, still maintaining the peculiarities of the base polymer.

The XELIGHT™ grades combine a good hydrolytic resistance and dimensional stability to a great processability and thermal resistance, furthermore, they are all colourable and available in biocompatible grades.

These new lightweight thermoplastic composites are the perfect solutions for many applications in the footwear world, especially where exceptional lightness, low density and great flexibility are required, always maintaining their excellent impact strength value.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XEBRID™

Thermoplastic composites

reinforced Carbon and Glass Fiber

XEGLASS™

Thermoplastic composites

reinforced Glass Fiber

Xenia® Materials and Jiejiayou (Shenzhen) Material Technology Co., Ltd together for the distribution in China of the products of the Italian company

Xenia® Materials, Italian company specialized in the development and engineering of high-performance thermoplastic composites reinforced fibres and additives, announces a new partnership agreement with Jiejiayou (Shenzhen) Material Technology Co., Ltd.

Thanks to this dedicated partnership, Jiejiayou (Shenzhen) Material Technology Co., Ltd will distribute Xenia® Materials thermoplastic composites families, XECARB®, XEBRID™ and XEGLASS™, within the whole Chinese territory.

The next Chinaplas exhibition, world’s leading trade fair dedicated to plastics and rubbers, that will take place in Shenzhen from the 13th until the 16th April, will serve as the opportunity for Xenia® Materials and Jiejiayou (Shenzhen) Material Technology Co., Ltd to present the main and latest news regarding thermoplastics and applications from the industrial sector to the sport system one.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XEBRID™

Thermoplastic composites

reinforced Carbon and Glass Fiber

XEGLASS™

Thermoplastic composites

reinforced Glass Fiber

XECARB® SL composites. The new super light structural family is born

XECARB® SL composites are the newest Xenia Materials family of Carbon filled, super light structural compounds developed in partnership with Arkema.

With a flexural modulus reaching 11000 MPa and a density equal to 1,00 g/cm3, the pioneer grade of this family was designed using Rilsan® PA 11. This polymer is obtained from renewable sources and is characterized by an outstanding toughness at low temperatures and great resistance to stress cracking.

These new compounds stand out for their high ratio between tensile strength at break and density, presenting an easy processability together with an excellent dimensional stability and great resistance to weather, UV rays and ageing. XECARB® 20-C15-SL grade reaches tensile elongation at break over 4% thanks to the intrinsic flexibility of the base polymer.

The XECARB® SL composites family embodies the perfect solution for special applications in drones, UAV’s and cobot industries, as well as for the most outstanding applications in the sport system sector.

Xenia is an Italian compounding company, specialized in engineering and production of innovative polymer based materials for the most advanced and challenging industries.

The company, located in Vicenza, Italy incorporates an engineering team, which helps customers to develop high-tech solutions with a research and development department dedicated to product innovation.

XECARB® HM

Thermoplastic composites

reinforced high-modulus Carbon Fiber

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XEBRID™

Thermoplastic composites

reinforced Carbon and Glass Fiber

PEBA and glass fiber. The flexible, structural and colourable polyamide

Forte dell’esperienza maturata negli anni con i PEBA caricati fibra carbonio, Xenia Materials introduce sul mercato XEGLASS® 17, famiglia di compound a base PEBA caricati fibra vetro.

Il PEBA è una poliammide flessibile senza plastificanti, con eccellenti capacità dinamiche, in grado di smorzare le vibrazioni ed il rumore anche ad alte frequenze. E’ caratterizzata da ottima resistenza all’usura, elevata resistenza a fatica, eccezionale flessibilità e resistenza all’urto in un’ampia gamma di temperature, bassa densità ed alta memoria elastica.

La combinazione con la fibra di vetro permette il raggiungimento di proprietà meccaniche altrimenti inarrivabili, ne enfatizza l’elevata resistenza agli agenti chimici e l’eccellente resistenza all’urto soprattutto alle basse temperature. I compositi XEGLASS® 17 hanno inoltre buona stabilità idrolitica e dimensionale, sono colorabili e disponibili anche in gradi biocompatibili.

L’ottima qualità estetica e la semplice processabilità contribuiscono all’impiego di XEGLASS® 17 nei settori degli articoli sportivi, dei beni di consumo e industriali.