XENIA SET TO UNVEIL NEW WHITENED SHADE MATERIALS AT JEC 2025

Xenia® Materials is pleased to introduce the Whitened Shade colour option to its carbon fibre reinforced grades. This new finish offers a lighter base colour compared to the natural black variant, making it colourable with masterbatch during the injection moulding and 3D Printing processes by pellets.

Carbon-fibre reinforced thermoplastics composites are highly valued for their strength, lightweight and durability, making them essential materials in sectors such as consumer goods, industrial applications and mobility. However, the natural black colour of carbon fibre, when combined with thermoplastic matrices, has traditionally limited its use in applications where design is important.

To overcome this challenge, Xenia has developed a new technology that produces carbon fibre reinforced materials with a whitened base colour. The result is a thermoplastic compound that not only offers excellent mechanical properties but also achieves a Whitened Shade colour, allowing it to be coloured by adding masterbatch during both the injection moulding and 3D printing processes by pellets.

Design

Performances

Lightweight

Colorability

Xenia will showcase its Whitened Shade materials at JEC World 2025, taking place from 4 to 6 March in Paris – France, at Hall 5, Booth D79.

XENIA MATERIALS COLLABORATES WITH POLITECNICO DI MILANO ON THE PRODUCTION OF A COMPETITIVE AIRCRAFT

Xenia® Materials is proud to have contributed to the success of Nyx, the innovative aircraft designed by Fly Mi – EUROAVIA Milano, the student association of engineers and designers from the Politecnico di Milano.

This project represents a significant achievement for both the Politecnico di Milano and Xenia Materials, highlighting how collaborations between industry and academic institutions can lead to groundbreaking advancements in innovation.

For the academic year 2023/2024, Fly Mi decided to participate in its first international competition: the Air Cargo Challenge, held in Germany last July.

Faced with the rules and restrictions imposed by the competition, the team developed and built Nyx, an ambitious drone crafted from composite materials. With a length of 1,5 meters and a wingspan of 3 meters, Nyx represents a remarkable achievement in engineering and design.

To meet the high demands of the Nyx project, Xenia Materials stepped in, supplying XECARB® 40-C20-3DP, a 20% carbon fibre reinforced polycarbonate specifically designed for Additive Manufacturing market. This material was essential in the creation of the moulds used for laminating the wings and control surfaces, which are crucial for the drone’s flight capabilities.

“With its low CTE values, the material provided by Xenia significantly reduced issues related to thermal shrinkage during the design phase, enabling us to produce higher-quality parts.

Furthermore, the absence of permanent deformations in the moulds after use, along with the resistance of internal surfaces to release agents, allowed us to repeatedly laminate the movable surfaces and test various internal configurations to find the best solution.” said the students who took part in the project.

The feedback of the engineers reflects how Xenia’s advanced material ensured the reliability and superior performance needed for the ambitious goal of the project:

“At Fly Mi EUROAVIA, we partnered with Xenia Materials to meet the demanding performance standards of our project. The lightness, recyclability and ease of handling of the moulds were key advantages, complemented by the increased sustainability of the process, adding significant value to our work.

Thanks to this collaboration, the Nyx project successfully achieved its ambitious goals, integrating advanced material science with pioneering aerospace engineering.” said M.H., serving as president of the Fly Mi Euroavia association at the time.

Discover more about the Academic & Research Support Program, Xenia’ s dedicated program for collaboration with universities, research centres and institutes of technology.

NEW RANGE OF MATERIALS MADE FROM 100% BIOBASED PA10.10

XECARB® 31 is Xenia’s latest addition to its Advanced Materials Collection.

This new carbon-fibre reinforced material, based on PA10.10, delivers exceptional strength and durability while being 100% bio-based.

This new material not only represents a step forward in performance but also aligns with Xenia’s commitment to sustainability.

With up to 50% carbon fibre reinforcement, XECARB® 31 ensures increased stiffness, making it ideal for structural applications that demand superior mechanical strength.

Furthermore, this new compound is well-suited for environments that require higher operating temperatures without compromising performance, thanks to its high melting point.

The PA10.10 base polymer ensures significantly reduced moisture absorption, improving long-term durability. Its excellent cold impact resistance makes it suitable for applications frequently exposed to low temperatures, such as outdoor environments and high-altitude settings.

The combination of lightweight construction and rigidity makes the XECARB® 31 optimal for high-performance sports equipment. This material enhances product durability without adding unnecessary weight, making it ideal for competitive sports where performance is crucial.

In the industrial sector, chemical resistance and mechanical stability are key advantages for parts exposed to harsh working conditions. This includes applications where the material’s ability to withstand heat, oil, and grease ensures longevity and reliable performance.

As a bio-based material sourced from castor oil, the PA10.10 significantly reduces dependence on fossil fuels, addressing the growing demand for eco-friendly solutions.

This new compound promotes a more circular and environmentally conscious approach to manufacturing, offering high performance without compromising on sustainability.

XECARB® 31 is available in the XERCARB®, XECARB® HM and XECARB® ST versions

100% Biobased

High Mechanical Properties

Chemical Resistance

Cold Impact Resistance

3DP MATERIALS

CARBON FIBRE REINFORCED PVDF

Xenia® Materials, global developer of carbon fibre reinforced polymers, presents its new range of PVDF-based compounds for 3D printing pellet-fed applications. This new group of materials ensures the carbon fibre properties mixed with the exceptional PVDF features, opening new opportunities for additive manufacturing production where high performance and chemical resistance is necessary.

Xenia® Materials is set to introduce to the market a 3D printing pellet version of the unfilled PVDF polymer and a groundbreaking range of carbon-fibre reinforced compounds. Carbon fibre is well-known for its great features in additive manufacturing, helping to prevent warping during the printing phase while maintaining a smooth surface finish, as well as ensuring dimensional stability and low thermal expansion. By adding carbon fibre to the base material, it enhances the qualities of the PVDF polymer. This new mix keeps the ease of use of regular PVDF while boosting strength and reducing electrical resistance, meeting ATEX standards.

According to Xenia’s R&D Manager Cristian Zanchetta, ” Xenia’s expertise in carbon-fibre reinforced polymer, applied to the PVDF polymer base, allows us to leverage our research and development know-how to push boundaries in creating innovative 3D printing materials. Our comprehensive materials portfolio now extends from unfilled PVDF to carbon-fibre-reinforced PVDF, fulfilling every client requirements.”

Xenia® Materials invites industry professionals to explore the new grades at TCT3Sixty 2024, taking place from 5th to 6th June in Birmingham, and at the FIP trade show in Lyon from the 4th to the 7th of June.

XEGREEN® 23-C20-3DP : 100% RECYCLED PET-G CARBON FIBRE REINFORCED GRADE FOR HIGH-PERFORMANCE ADDITIVE MANUFACTURING

Xenia® Materials, global player in high-performance fibre-reinforced thermoplastic composites production, proudly announces the debut of XEGREEN® 23-C20-3DP at JEC World 2024 (HALL 5, BOOTH C79), the premier event for the composite materials industry.

This innovative material marks a significant leap in additive manufacturing, bringing forth unmatched performance, sustainability, and versatility.

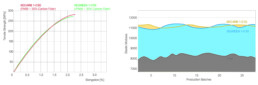

XEGREEN® 23-C20-3DP, a PET-G (polyethylene terephthalate glycol-modified) with 20% carbon fibre reinforcement, represents a meticulous engineering effort to meet the demands of applications requiring superior strength, minimal warpage, and environmental responsibility.

Moreover, excelling in low-temperature environments, XEGREEN® 23-C20-3DP finds suitability across various applications, from prototyping to master moulds and finished parts. Beyond immediate advantages, this material guarantees long-term performance, ensuring durability and stability over time.

XEGREEN® 23-C20-3DP offers a distinctive set of features, ensuring optimal performance and sustainability throughout its lifecycle. Its advanced formulation minimizes warpage during the printing process, providing manufacturers with reliable and consistent results. Designed to withstand harsh chemicals, this material is an ideal choice for the carbon fibre lamination process, thanks to its resistance to resins and release agents.

This new grade reflects Xenia® Materials commitment to environmental sustainability. Manufactured from 100% fully recycled materials, it contributes significantly to a circular economy.

Xenia® Materials invites industry professionals to delve deeper into XEGREEN® 23-C20-3DP at JEC World 2024, taking place from 5th to 7th March.

Visit us at Hall 5, Booth C79, where our team will be available to provide detailed insights, answer questions, and explore how this innovation can elevate your additive manufacturing processes.

Xenia® 3DP Materials Official Debut

Xenia® Materials, a global player in speciality thermoplastic compounds, announces the introduction of its new range of 3D printing materials at FORMNEXT – EXPO 2023.

This comprises of unique resins combined with fibre and additives, functionalised for use in any pellet-based type of FDM printer, for LSAM production as well as high-precision production.

These high-performance composites 3DP MATERIALS display impressive stiffness, dimensional stability, low density as well as low thermal expansion and high durability at both high and low temperatures.

Based on the pre-existing wide range of its product families, painstakingly developed throughout the company’s history, Xenia® offers its customers the same Xecarb®, Xebrid™, Xelight® and Xegreen® materials, now dedicated to 3D printing.

New-market challenges are the drivers instigating the co-innovation with our customers and partners to expand the possibilities into AM. These high-performance, recyclable materials are suitable for a wide range of applications and markets, from industry through sport to sustainable mobility and defence.

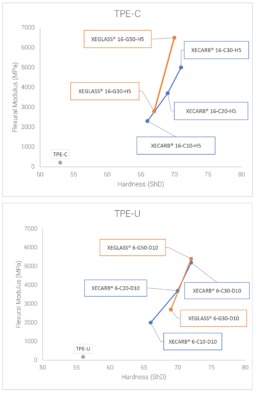

Soft Materials™: Flexible Thermoplastic Composites

SOFT MATERIALS™, the new family of flexible thermoplastic composites based on elastomers reinforced with carbon as well as glass fibres, developed by Xenia, makes its debut at the FAKUMA International Trade Fair held in Friedrichshafen from 17th to 21st October 2023.

The range has been conceived with the express intention to offer a range of polymeric resins having different physico-mechanical properties but sharing intrinsic elasticity.

Combined with carbon- as well as glass-fibre reinforcement, the SOFT MATERIALS™ family offers an extraordinary range of technical solutions in terms of lightness, rigidity and impact resistance extending to low temperatures.

In applications extending from sport systems through robotisation to autonomous mobility, SOFT MATERIALS™, with their unique combination of features, offer to designers and engineers a new toolbox with which to tackle the most difficult challenges in today’s market.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XEBRID™

Thermoplastic composites

reinforced Carbon and Glass Fiber

XEGLASS®

Thermoplastic composites

reinforced Glass Fiber

XEGREEN®, THE 100% SUSTAINABLE VISION OF XENIA® MATERIALS.

The XEGREEN® thermoplastic composites family is the result of the association between recycled, rigorously selected and certified fibres and polymers from wastes and end-of-life products.

Consistent with the vision that distinguishes Xenia, the peculiarity of these materials is to guarantee high mechanical performances and lightness, while maintaining constant processability between different batches.

As a result of its technical knowledge in the development and the production of high-performance thermoplastic composites, Xenia ensures characteristics comparable to the corresponding virgin materials and engineers formulations and solutions to meet the technical specifications required by the applications.

In recent years, environmental awareness and the commitment towards the realisation of more sustainable materials have spurred manufacturers to search for solutions to replace virgin plastic materials with recycled ones. The goal is to reintegrate a part of the wastes back into the production chain.

Unfortunately, this transition is often limited because of the poor mechanical performance of these materials, making their use impossible where such requirements are fundamental.

XEGREEN® was precisely born from the desire to overcome this barrier, enabling the replacement of structural high-quality materials with alternative products from recycled wastes. XEGREEN® offers the possibility to take a fundamental step towards a sustainable future to all market operators who need these types of materials for applications where mechanical strength and lightness are prime requisites.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XEBRID™

Thermoplastic composites

reinforced Carbon and Glass Fiber

XEGLASS™

Thermoplastic composites

reinforced Glass Fiber

Xenia® is giving a new look to its bio-based products

Xenia® is giving a new look to its bio-based products

A new web appearance will define Xenia’s high-performance thermoplastic polymers derived from renewable sources. All of the current bio-based products in our catalogue will, from now, include the renewable content in their technical datasheets. A small difference, which is however an essential issue in an increasingly environmentally sustainable world.

XECARB®

Thermoplastic composites

reinforced Carbon Fiber

XELIGHT™

Ultra-light

Thermoplastic composites

XEGLASS™

Thermoplastic composites

reinforced Glass Fiber

Xenia® Thermoplastic Specialties launches XECARB® ST supertough carbon fiber composites

Xenia® Thermoplastic Specialties launches new range of supertough carbon fiber composites

New XECARB® ST family of carbon fiber reinforced thermoplastic composites combines advanced lightweighting benefits with superior impact strength.

Xenia® Materials, a global leader in thermoplastic specialties, has announced the introduction of XECARB® ST, a new family of supertough carbon fiber composites custom-engineered to close a performance gap in the market and provide superior impact strength performance.

“There is a growing demand for lightweight composites in various new markets, such as sustainable mobility and unmanned aerial vehicles (UAVs), where we have identified a need for higher impact resistance than previously offered by carbon fiber reinforced composites,” says Cristian Zanchetta, Technical Manager for R&D at Xenia® Materials. “Our new XECARB® ST family meets these challenges while at the same time opening new opportunities for innovative applications in existing market segments, such as sports equipment, appliances, supercars and even additive manufacturing.”

XECARB® ST builds on the proven mechanical strengths of Xenia®’s successful XECARB® range, but shows significantly higher notched impact resistance, low temperature ductility and tensile elongation at break. With slightly lower density, the new carbon fiber composite technology offers these unmatched advantages together with further lightweighting possibilities. Major customers seeking to improve the impact and cold impact performance of carbon fiber composite applications are already evaluating the added potential for weight reductions, lower material and energy consumption, associated cost savings and reduced environmental impact.

XECARB® ST thermoplastic composites are based on selected polyamide matrix materials – PA66, PA6, PA11, PA12, PA6.10, PA6.12 and PA4.10 – addressing different mechanical, thermal and physical requirements. Standard carbon fiber content is 30 percent (CF30). The PA6-based composites are also available as CF20, CF25, CF35 and CF40 grades. In addition, the portfolio includes two high-modulus materials for enhanced flexural strength, and provides a wide engineering window for further customization depending on specific application needs.

“Beyond winter and mountain sports equipment from boots and running shoes to bikes, these new high-impact carbon fiber composites will help us reach into other markets and further expand our customer base in Europe, APAC and North America,” adds Enrico Mancinetti, Sales Manager. “Driving this growth, Xenia® Materials will also increase its European sales force with a strong focus on qualified local customer support and service.”