Research topic:

Rebound And Damping Behaviour Of Fibre-Reinforced Thermoplastic Polymers: Guidelines For The Development Of Injection-Moulded Sport Equipment

Xenia Materials, in collaboration with the Sport Technology Lab at the University of Bologna, has developed an innovative test method to optimize the rebound and damping behaviours of fibre-reinforced thermoplastic polymers, essential for high-performance sports equipment.

The test has shown that it is possible to choose thermoplastic composite materials tailored for specific applications, with the desired rebound and damping characteristics, by selecting the correct combination of fibres (amount and type) and of polymer matrix.

Fibre-reinforced polymers are more widely used in sports equipment than non-reinforced polymers, due to their higher mechanical properties. Moreover, this class of composite materials offers significant advantages in terms of processing and recyclability when compared to thermoset-based composites.

Another quite unique feature of fibre-reinforced polymers is that they offer the possibility of using a wide range of combinations of polymer matrices (with completely different viscoelastic properties) and fibre content and types.

This allows a very high number of materials with a broad range of mechanical and viscoelastic properties to be obtained, and therefore to finetune the choice of material for a specific application.

Characteristics of the materials

The fundamental physical characteristics determining the selection of materials suitable for sports applications are:

– Stiffness/weight ratio

– Stress and strain at break

– Impact resistance

– Elastic-return velocity (rebound)

– Vibrational damping capacity

– Variation of stiffness as a function of temperature

While the first 3 characteristics have been widely studied and reported on for polymer-based composites, the latter 3 are generally not analysed. And yet, these properties have significant effects on sports performances. Indeed, sports are performed with cyclic applications of forces and the rebound has a significant effect on sports performances, for example in skiing and running. On the other hand, vibration damping has a great effect on control, comfort and performance in disciplines like cycling and skiing.

It is generally assumed that a material with a fast rebound does not provide good damping properties. This assumption is not always true for composite materials, since rebound and damping properties depend both on the type of fibre and on the matrix used. In addition, several sports are played in outdoor conditions at variable temperature.

A novel method to test specific properties

All polymer-based materials increase their stiffness by decreasing temperature due to the reduced segmental mobility of the polymer chains. At the same time, the stiffness/temperature relationship depends on the polymer’s chemical and physical structure.

Since these important characteristics of composites are generally neglected, in collaboration with the Sport Technology Lab of the University of Bologna, Xenia has developed a novel method for testing these properties. They also have created a ranking system to give customers an indication of rebound, damping and temperature dependence of their polymer-based composites.

A test bench for measuring composite materials‘ rebound and damping characteristics has been developed and built for this specific purpose.

The system locks one part of the specimen to the base, while the upper part is flexed with a cable attached to a tensile testing machine able to measure the displacement and the force applied. Once a certain deflection is obtained, the specimen is released, and the damping curve (position vs time) is measured using a laser detector that records at 1 kHz.

Figure 1: particular of the test bench used for the tests.

Test results

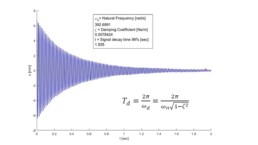

The damping curves have been interpolated using a model of the second order with a sinusoidal response that makes it possible to obtain the damping coefficient and the natural frequency (Figure 2).

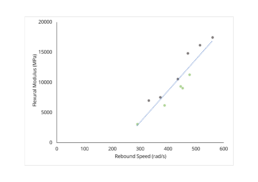

The elastic-return velocity (rebound) has been evaluated on the basis of the natural frequency measured during the test. Figure 3 shows the effect of flexural modulus on rebound speed. A linear correlation between stiffness and rebound speed may be noticed that is not dependent on the polymer matrix of the composite.

This is a clear indication the desired rebound speed can be obtained by tailoring the stiffness, which can be achieved by changing the amount and type of fibres in the composite.

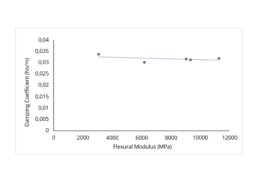

The vibrational damping capacity has been evaluated on the basis of the damping coefficient determined from the time/displacement curves (Figure 4).

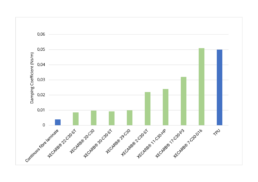

Damping has been found to be dependent on the matrix type and independent from the stiffness of the material for all types of matrices analysed. Significant differences have been observed when changing the matrix (Figure 5) with damping characteristics that can vary between those of a standard TPU (with high vibration damping) and those of a continuous fibre composite laminate (with low vibration damping).

Figure 4: Damping coefficient vs flexural modulus for PEBA-based composites.

Figure 5: Damping coefficient for composites with 30% carbon fibre content and different polymer matrices.

Outdoor sports are practiced at widely-varying temperatures. All materials become increasingly stiff as temperatures decrease, but in different amplitudes. To evaluate stiffness as a function of temperature, DMTA analyses were carried out in a range from -40°C to 80°C. We have found that the temperature vs stiffness behaviour depends almost completely on the type of polymer matrix used and to a very minor extent on the type and amount of fibre used.

As an example, Figure 6 reports the stiffness variation between -10°C and +23°C, showing that a 35% difference can be obtained by changing the polymer matrix. This is a clear indication that, by using DMTA analysis, it is possible to choose the material with the desired variation of stiffness in the temperature range of use.

Figure 6: Comparison between tensile modulus at 23°C and -10°C for composites with 30% carbon fibres and different polymer matrices.

Conclusion

This study, performed in collaboration between the Sport Technology Lab at the University of Bologna and Xenia, has demonstrated the great potential of thermoplastic polymer-based composites in sports equipment production.

This is an application in which specific rebound, damping and stiffness change with temperature characteristics are required. For this reason, Xenia begun to report this data to help customers select the best materials for their specific applications.

The results obtained clearly show that it is possible to design materials for specific applications, with the desired rebound and damping characteristics, by choosing the correct type and amount of fibres combined with the correct matrix. This is because rebound is governed by composite material stiffness while damping is determined by the type of polymer matrix used.